Scan QR code

Scan QR code

1 Product Overview

LM-K Anti-Rutting Agent is a product that was specially developed for enhancing the anti-rutting performance of LM series products. The product is a pavement material in form of even black particles. It is processed through melt blending (Physical blending modification) with asphalt as its main raw material, and high polymer organic compounds as supplementary materials. It can be input during the process of aggregate blending for asphalt mixture. It melts and scatters rapidly, greatly enhancing the anti-rutting performance, water damage resistance and anti-aging performance of asphalt mixture. Meanwhile, it satisfies other index requirements of asphalt mixture.

2 Reference Mix Amount

Normally, the mix amount for both domestic and overseas anti-rutting agents is 0.3-0.5% of asphalt mixture. The mix amount for LM-K is 0.3%-0.8% of asphalt mixture, which has a wider range and is more convenient for modification. The mix amount can be determined according to different levels of highway. Besides, the application of LM-K can appropriately identically replace base asphalt or modified asphalt.

3 The Application Advantage of the Product

|

A Comparison between LM-K Anti-Rutting Agent and Similar Ones |

||

|

Items |

LM-K Anti-Rutting Agent |

Common Anti-Rutting Agent |

|

Ingredients |

Congeneric with asphalt |

Recycled Plastic |

|

Mix Temperature |

175℃-185℃ or slightly lower |

>200℃ |

|

Construction Cost |

Can identically replace asphalt |

Cannot reduce asphalt consumption |

|

Aging Resistance |

Stable, aging slowly |

Aging fast, performance decay fast |

|

The Advantage of LM-K |

1. Excellent compatibility with stone and asphalt, with low heating temperature and short blending time; 2. Asphalt consumption can be reduced according to mix proportion, other indexes are better. 3. Stable and anti-aging 4. Very good adhesion with both acidic and alkaline stones, which can reach level 5. 5. It has a price advance compared with foreign similar products |

|

LM-K is not particular to the pH value of stone.The adhesion of acidic stone can reach level 5 with LM-K mixed。

|

|

||

|

Sample of acidic stone (Granite) |

(LM-K+granite+base asphalt)water boiling method; before aging:asphalt covers well,the asphalt film is bright and dense. |

After aging:the asphalt film covers still well,there are few small spileholes on the surfaces of aggregate. |

5 Product Transportation

The LM series products should avoid sun exposure, keep away from Moisture, contamination and scratches during transportation. Keep the outer packing in good condition. In case of complete packaging, general cargo transportation standard applies.

6 Product Storage

The LM-K product should be stored in a dry, ventilated place. They should avoid ultraviolet irradiation. Stop Kindling. They cannot be stored together with organic solvents. The LM series products can be stored long-term at room temperature.

7 Product Packaging

Particles in bags(25kg/bag)

International universal valve bags are applied, with strong tear resistance and low broken package rate, reducing storage room.

Convenient transportation,reducing logistics cost, energy-saving and environmentally-friendly.

The design method for bitumen concrete does not change, after mixing LM-K, an identical or partial amount of bitumen can be replaced, which does not change the designed mix proportion for bitumen mixture and its bitumen aggregate ratio.

1. LM-K cannot be directly input into bitumen. It must be blended evenly with the aggregates and then input the bitumen. Before testing, calculate the required amount of the materials according to the requirement of tested items. Pay attention: an identical or partial amount of bitumen can be replaced, with LM-K mixed.

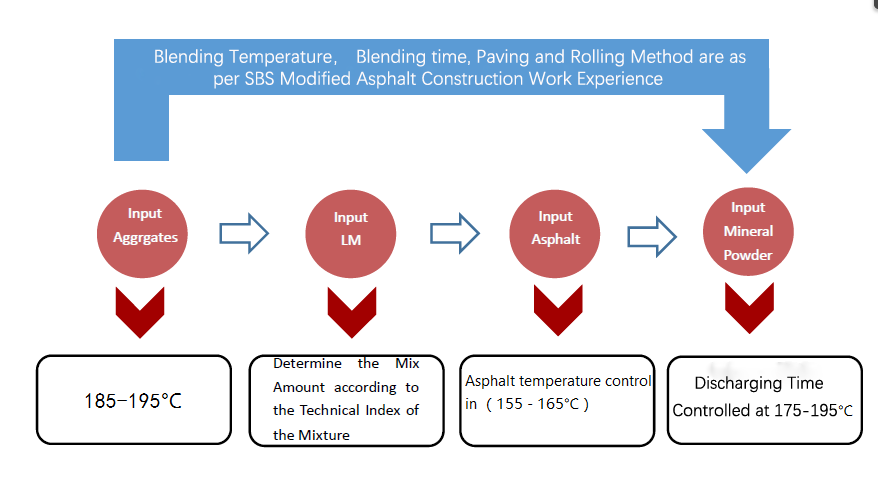

2. Measure the aggregates with different sizes according to calculation. After mixing, heat them to 185-195℃ (the actual aggregate temperature) and maintain constant for 4 hours. Meanwhile, heat the bitumen to 155-165oC, standby. Set the mix pot temperature at 185oC.

3. First, when the mix pot temperature reaches the set value, input the aggregates blending;

4. Then input LM-K, dry blending with the heated aggregates for 90 seconds.

5. After that input the base bitumen into mix pot, blending for another 90 seconds.

6. Finally, input the mineral powder into mix pot, blending for another 90 seconds.

7. During the whole process of testing, the blending temperature is controlled at 185-195℃.

8. When the mixing completes, input the mixture into the mold and compact. The

compaction temperature is 175-185℃ (the measured temperature).

(Sample Testing: Test according to 《JTG E20-2011 The Test Procedure for Highway Engineering Bitumen and Bitumen Mixture》. Clients can select test methods according to actual situation)

(1)LM-K cannot be directly input into the bitumen, it must be input in the mix pot either simultaneously with the aggregates or 1-2 seconds after it, then input the bitumen.

Before production in the blending tower, calculate the required amount of materials according to the production quantity of bitumen mixture per pot and its bitumen and aggregates ratio. Pay attention, LM-K can identically or partially replace base asphalt.

(2)Control the aggregates heating temperature at 185-195℃,input them into the mix pot. The LM-K is input into the mix pot either manually or via air conveying machine at the same time with the aggregates. (If it is input manually, input it through the viewport all at once, in case of air delivery, it is transmitted into the mix pot via conveying pipe, which is connected with the viewport)

(3)After inputting the aggregates and LM-K, input base Bitumen. (The bitumen temperature is controlled at 155-165℃). Blend all together.

(4)Finally, input mineral powder and blend together.

(5)Items 1- 4 is the advice on the production process for inputting LM-K anti-rutting agent. Principally, the addition of LM-K does not change the existing production process. The input order of all ingredients and the mixing time of each section are conducted according to the successful local experience.

(6)The discharging temperature is controlled at 175- 195℃.